Processes

The surface currently used for warehousing is 800 m2, that of converting 400 m2 and that of end product storage is 200 m2. Inside, the specialist staff thanks to the technologically advanced machinery can implement punching, cutting, rewinding, coupling and third party processes always guaranteeing quick delivery times (max. 48 hours all over Italy) and contained costs. A brief overview:

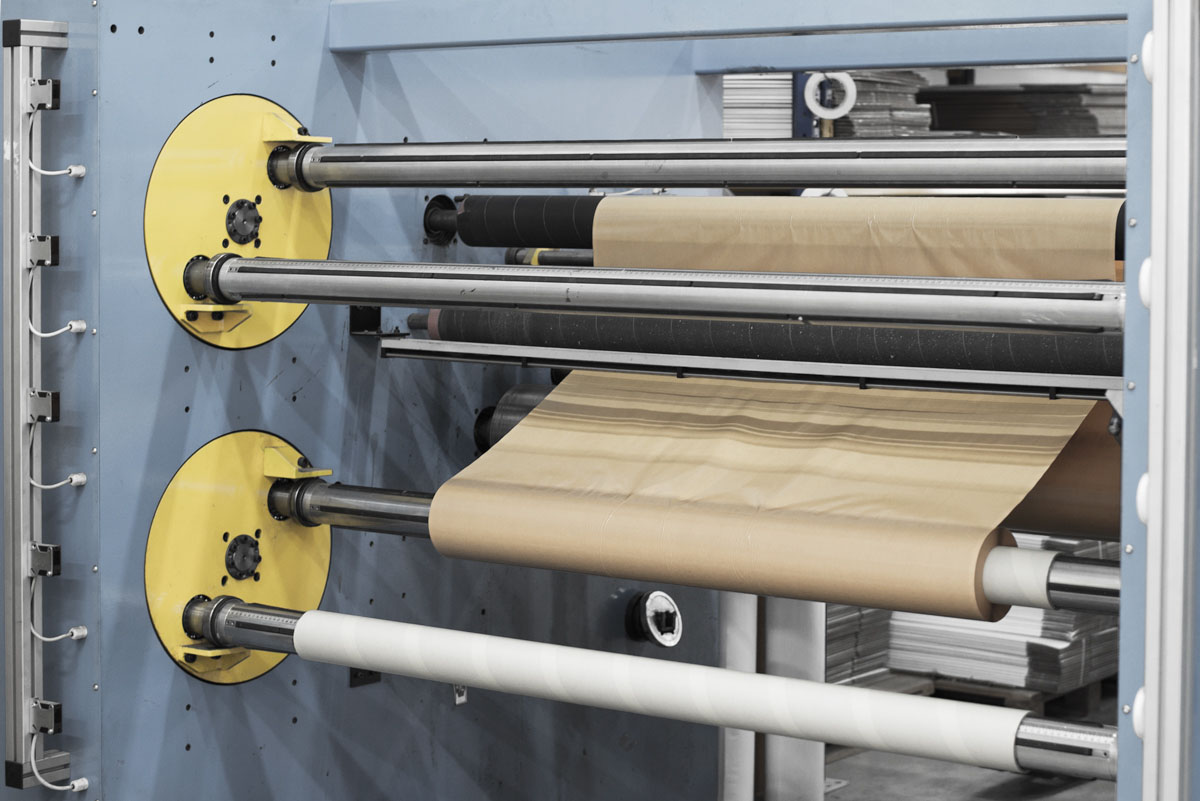

Rewinder with double revolver BA-1600

Possibility of rewinding and in-line cutting with automatic selvage recovery. High productivity. Clearance: 1600 Speed 100 m/min

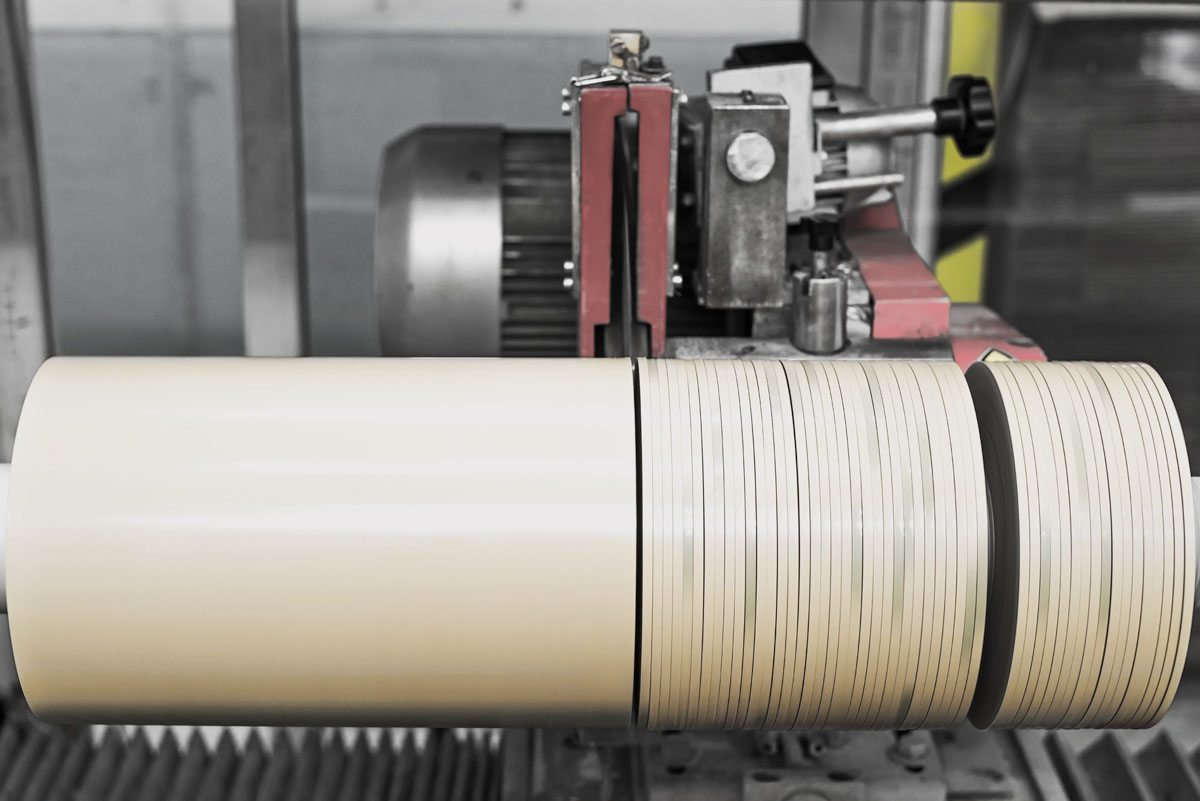

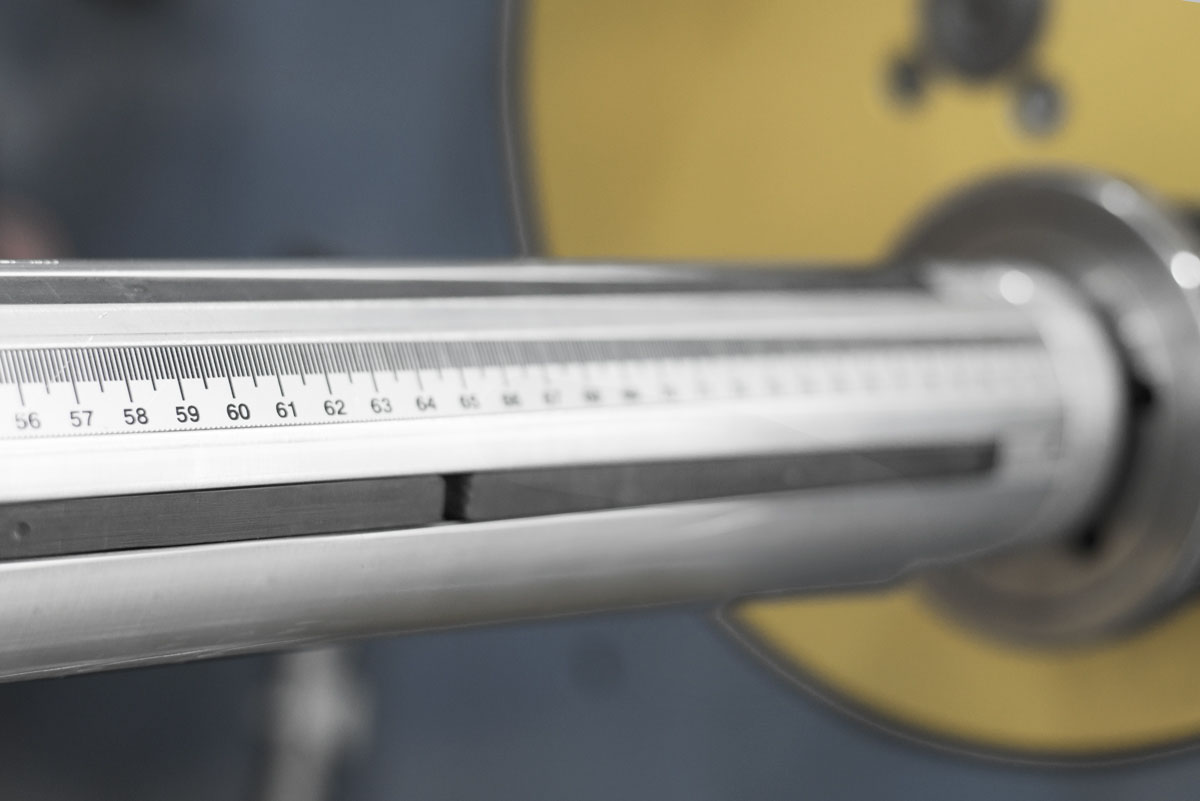

Automatic reel cutting lathe TL-450

Highest quality and precision cutting. Maximum tolerance 0.05 mm Clearance 1600 Cutting range: from 0.25 to 1600 mm

Automatic reel cutting lathe T-400

Highest quality and precision cutting. Maximum tolerance 0.10 mm Ideal for single and double sided foams Clearance1600 Cut: from 4 to 1600 mmpe

Flat puncher GD-151D

Adhesive and non-adhesive material punching, to a maximum size of 150 mm per side.

Punched materials are arranged on continuous monosiliconed paper or in blocks, with or without scraps.

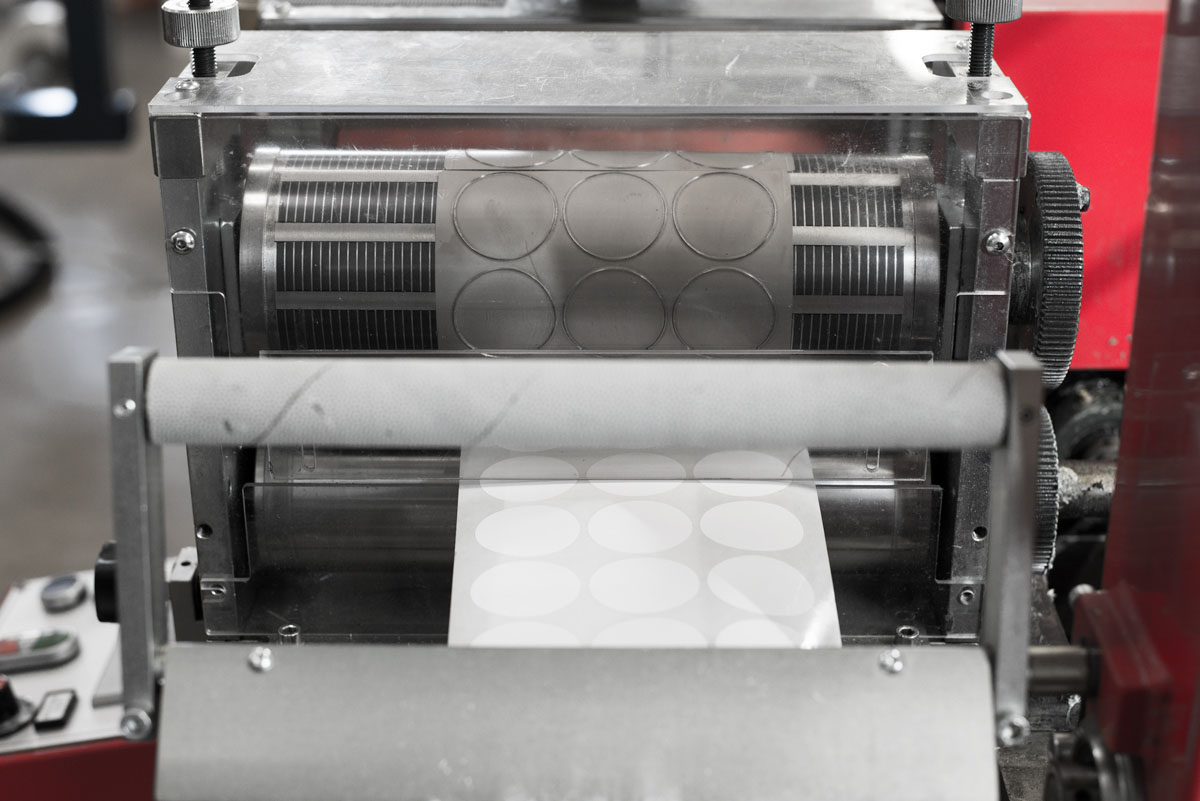

Rotary punchers GDR-250 e FR-250

Adhesive and non-adhesive material punching, to a maximum size of 250 mm per side.

Punched materials are arranged on continuous monosiliconed paper

or in blocks, with or without scraps. Possibility of creating punches with tabs for easy removal.

Calender CAL-1600

Calender for various processing: - coupling of materials in various thicknesses, maximum 80 mm, max width 1500 - replaces Liner - creation of sheets in various sized measures on request.

Spooling machine ET-T2

Spooling machines to create double sided and single sided adhesive spools. Lengths from 500 to 5000 metres. Can also be created using minimum quantities.

Sheeting machine TF-500

Sheeting machine for the production of punched double sided adhesive in blocks.