HIGHER GLUING, HIGHER SPEED

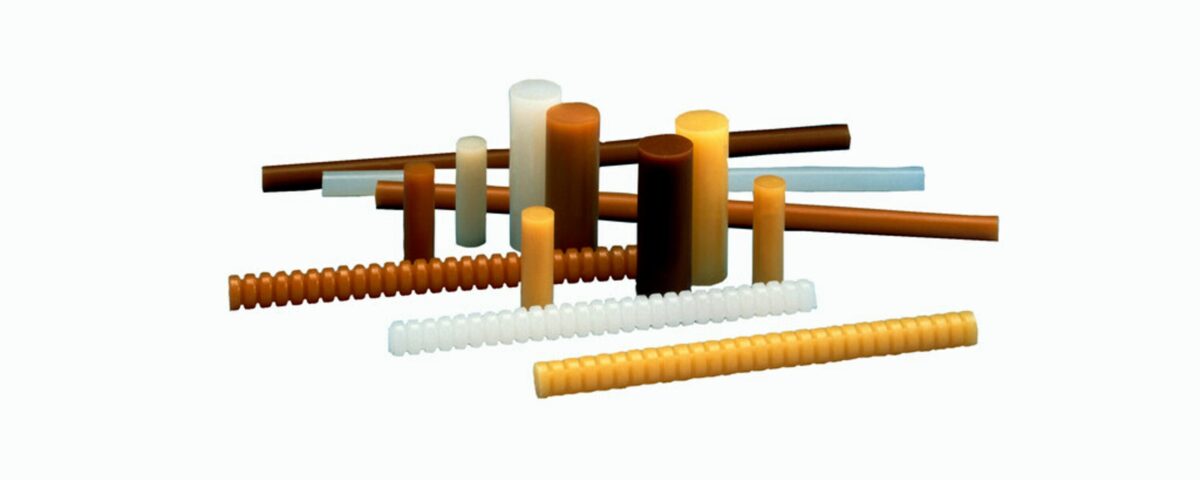

Hot Melt 3MTM adhesive . Improve productivity and aesthetics while reducing costs and minimizing waste with the Hot Melt 3MTM adhesive system, an environmentally friendly and virtually odorless bonding solution.

Fuel and oil and an exposure time that allows adaptation and positioning. This adhesive offers optimal performance when used with our 3M hot melt applicators. PG, TC with Quadraci kg and EC.

MAIN CHARACTERISTICS

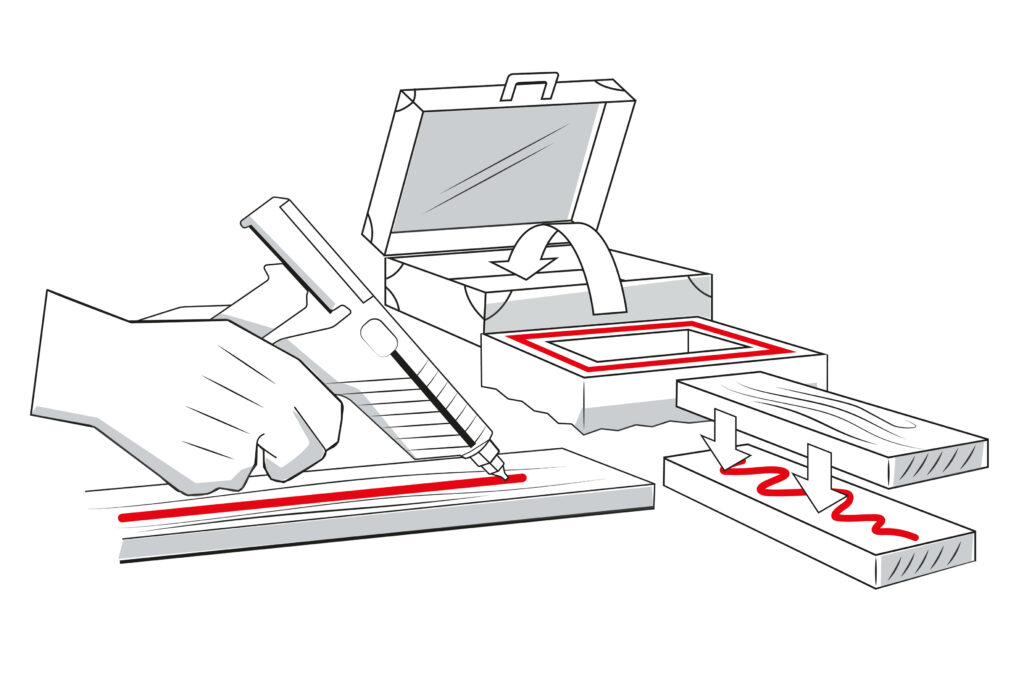

3M Hot Melt can be used in many industries for numerous applications, including: Wood-to-wood assembly of non-structural components (home and office furniture and cabinets).

These adhesives are designed to melt again after fixing if exposed to sufficiently high temperatures. The advantage of Hot Melt adhesives is that they are practically invisible between two surfaces, unlike mechanical fasteners and sealing tapes

USERS ADVANTAGES

- It improves the speed and ease of production, you can immediately move the assembled parts and eliminate clamps, fixing types, drying times and energy.

- Low melting point adhesives are available for lower operating temperatures for bonding heat sensitive surfaces.

- Excellent hot adhesion quick setting for corrugated board, repackaging recycled chipboard and wood

- Excellent impact resistance good resistance to cutting and peeling

- Fast and durable product performance for small joints, fixing and finishing, laminating large surfaces and more

- Open time allows adjustments and positioning

- Excellent electrical and anti-corrosive properties for copper make it the ideal solution for electrical applications

- High flow in long open time output