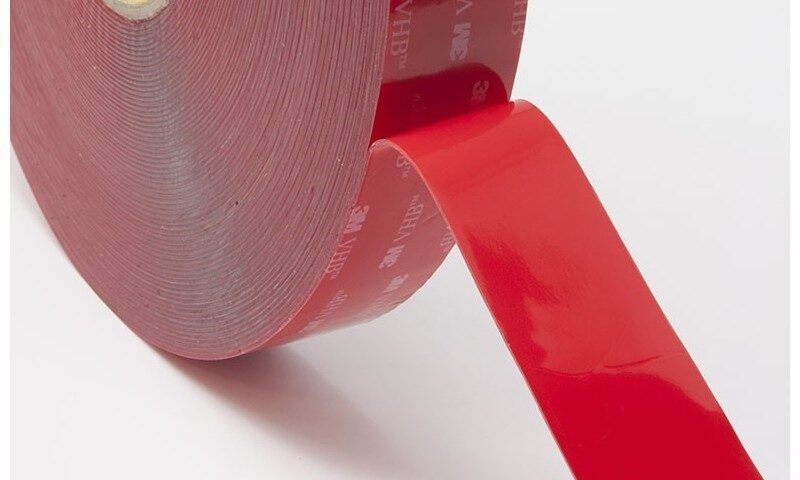

The very high bond (VHB) tapes invented by 3M in 1980 were the first of their kind.

These exclusive tapes combine conformability with a durable permanent fastening.

The result is a family of extremely durable tapes, able to adhere to a wide range of substrates.

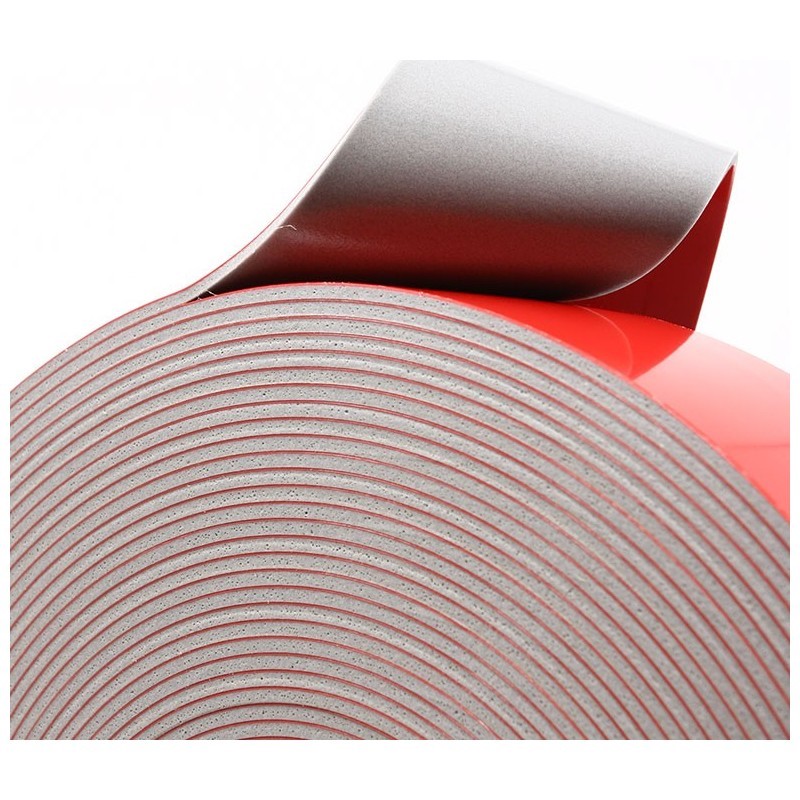

Non Traditional Foam Tape

They are alternative and high performance solutions compared to traditional mechanical assembly systems such as rivets, screws and welds.

VHB tapes are viscoelastic: being made of a homogeneous acrylic adhesive mass, they are able to absorb dynamic stress and then return to the original shape while maintaining the characteristics of cohesion and sealing.

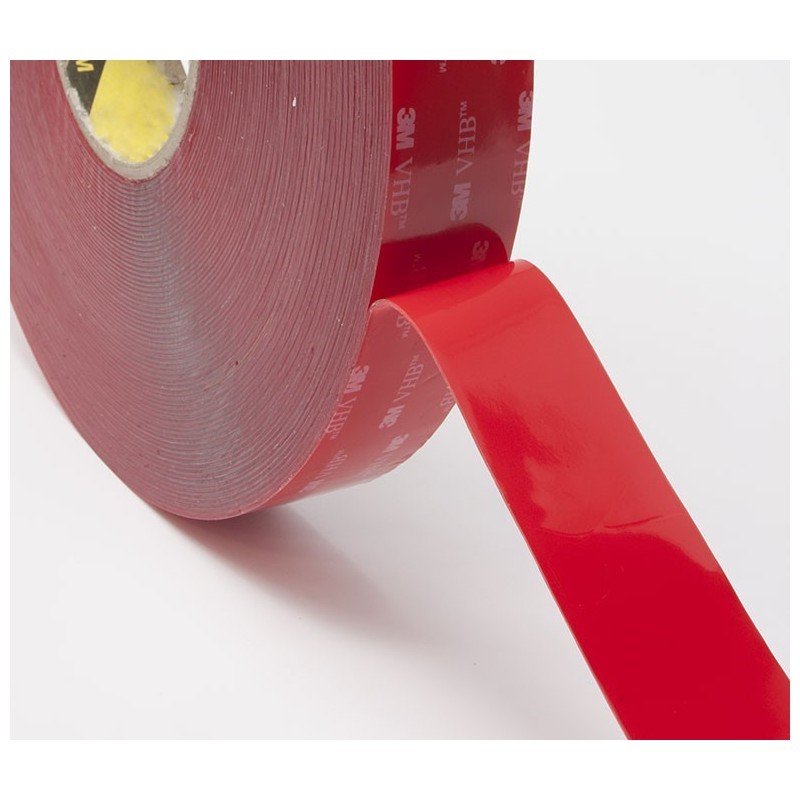

The use of VHB double-sided adhesive ensures the assemblies greater quality and strength, better aesthetics, less vibration and more corrosion resistance external agents.

This tape is safe and reliable offers uniform fixation, exceptional strength and excellent resistance to solvents and moisture, improves the appearance of finished products by eliminating rivets and screws while offering the possibility to immediately handle the assembled product.

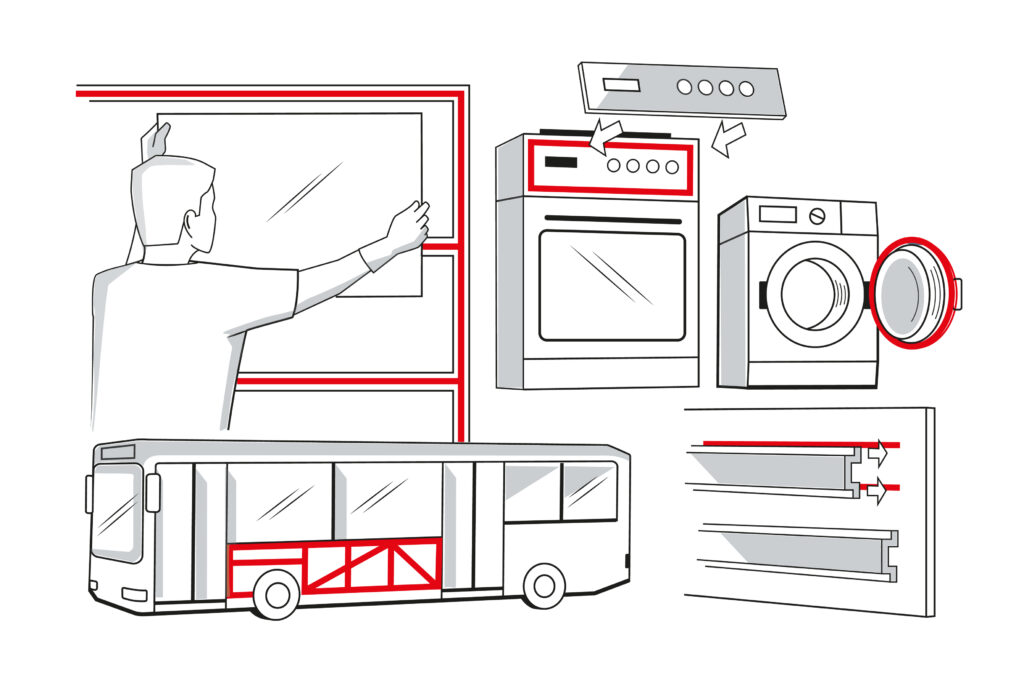

Fastening with 3M™ VHB™ tapes allows for a faster process with mechanical methods or with the use of a liquid adhesive. This versatile line of tapes can be used internally or externally and in various applications, including window, door and sign assembly and in applications for the electronics, construction and many other industrial applications.

The tape 3M™ VHB™ is resistant to chemicals, is not subject to changes due to UV rays or temperature changes and is able to tolerate the heat of Dubai and the cold of Canada. The unique chemical composition of the acrylic adhesive is particularly robust, does not change over time and therefore makes this product a durable and strong tape to rely on.

Advantages for use

- Invisible bonding: improves the aesthetics of your project with virtually invisible fasteners.

- Streamlines production processes: Provides a seal that allows immediate handling and allows you to route glued parts more quickly through production operations without any hardening time

- Allows the use of materials: dissimilar thinner and lighter

- A lasting difference: with a bond built to withstand More extreme temperatures, 3MTM VHBTM tapes, withstand hot, cold and cyclic temperatures, UV light, moisture and solvents.

- Adhesive strength: For your toughest bonding applications, 3MTM VHBTM tapes distribute dynamic or static stress across the entire bonded joint surface, improving sealing resistance and eliminating the need for mechanical fasteners.

- Energy absorption: Stress and energy are absorbed into the foam and not transferred to the junction line.

- Stress relief: over time, stress is released from the joint and absorbed by the foam.

Where you can apply them:

- Gluing of panel to cloth

- Fixing the reinforcement to the panel Gluing of decorative material, finishes, accessories

- Gluing of identification plates, signal logos

- Gluing electronic displays

- Gluing window lenses in the housing

- Joints of transparent material

- Mounting of backlit translucent signals

- Assembly of components prior to hot curing processes such as powder or liquid coating